Shot blasting machines are essential in the Noida blasting industry for surface preparation and finishing. These unique pieces of equipment bring accuracy and efficacy to a wide range of businesses. They play an important role in increasing productivity and product quality in the automotive and construction sectors. They are equipped with cutting-edge shot peening machine technology, ensuring consistent surface treatment, durability, and strength. These machines, when paired with strong shot blast compressors, create high-performance results, making them an important resource in the Noida industrial ecosystem.

We are the leading sand blasting, grit blasting, and shot blasting machine manufacturers in Noida, India.

Shot Blasting Machine

A shot blasting machine is a piece of specialist equipment that is used in a variety of industries for surface cleaning, preparation, and finishing. It is an enclosed piece of equipment that cleans and prepares metal, stone, steel sheets, and other rough surfaces using an abrasive shot blasting machine in Noida. It uses abrasive materials, such as steel shot or grit, propelled at high speeds to remove rust, scale, paint, and other impurities from surfaces. Shot blasting devices are available in a variety of forms, such as wheel blasting, air blasting, and tumblast systems, to accommodate diverse workpiece sizes and material kinds.

The type of shot-blasting machine determines how fast and under what pressure it operates. In shot blasting machines, blast material is thrown at high speeds in a carefully regulated manner. It used abrasive impact to remove dust, paint, and pollutants from the surface. The shot blasting technique uses compressed air to propel the abrasive media on the equipment at high speeds.

Aerowheel Surface Finishing Solutions is a leading manufacturer of automatic sandblasting machines, abrasive blasting cabinets, portable sandblasting equipment, and shot blasting machines. AWSF Solutions, which operates in Noida, Pune, Delhi, Ghaziabad, Gurgaon, Bangalore, Hyderabad, Chennai, and numerous other locations, leads the industry with its comprehensive range of surface finishing solutions.

Shot Blasting’s Role in Enhancing Surface Finish for Automotive Parts

One of the primary benefits of shot blasting in surface finishing is its ability to provide a consistent surface texture on a wide range of automotive parts, including chassis components, engine blocks, brake components, and suspension parts. This consistency is required to ensure that the end items perform well, function properly, and are visually appealing.

Furthermore, shot blasting is an effective way to prepare the surface of automobile parts for future procedures including painting, coating, plating, and welding. Shot blasting improves coating and finish adherence by eliminating surface impurities and providing a roughened surface profile, increasing the overall durability and lifetime of automotive components.

Shot blasting improves not just surface aesthetics and functioning, but also the overall quality and reliability of automobile parts. Shot blasting prevents premature wear, corrosion, and structural failures by reducing surface flaws and inconsistencies, hence improving vehicle performance and safety.

Advantages Of Shot Blasting Machine

1. Take Price Advantages

The shot blasting machine price process improves the lifespan and durability of future films.

2. Latest Machine

The price of shot blasting equipment increases flexibility in order to improve paint adhesion.

3. Shot Blasting Machine Price

Shot blasting machine price effectively reduces preservation expenses by increasing coating life.

Types of Shot Blasting Machines

Air Operated (Pneumatic) Shot Blasting Machine

Shot blast nozzles are utilized in air-operated shot-blasting machines, which rely on compressed air for the shot-blasting process. These pneumatic shot-blasting machines, including shot-blasting cabinets, offer optimal flexibility for lower production applications. The method employed by air-operated shot blasters is straightforward, where the shot is propelled horizontally through a rubber shot blasting pipe and Shot Blast Nozzle assembly. This setup facilitates finishing operations on steel frames and weldments, effectively replacing manual tools. Consequently, the cost of implementing an air-operated shot blasting machine in a production line tends to be higher compared to a centrifugal wheel blasting machine.

Type of Air-Operated Shot Blasting Machine

- Portable Shot Blasting Machine

- Cabinet Type Shot Blasting Machine

Portable Shot Blasting Machine

A portable shot-blasting machine is a versatile variation of the shot-blaster apparatus, intended for mobility based on individual requirements. These machines have the advantage of accepting different abrasive media according to customer requirements. Shot blasting machine suppliers in Noida provide a wide range of abrasive choices, which may be created to individual surface cleaning requirements. These portable devices are classified according to their abrasive tank capacity and surface cleaning rate, ensuring that consumers have efficient and adaptable blasting solutions.

Type of Portable Shot Blasting Machine

- Shot Blasting Machine, Airo P7 150

- Portable Shot Blasting-Machine Airo P7 300

- Portable shot blasting machines, Airo P7 500

- Portable shot blasting machine, Airo P7 1000

Shot blasting Cabinet

A shot blasting cabinet, supplied by shot blasting machine suppliers, is an enclosed apparatus equipment various components designed for roughening the surface of substrates. The process involves utilizing blasting abrasives such as steel shot, stainless steel shot, aluminum oxide, mild steel shot, 30/60 Mesh, abrasive garnet, steel grit, aluminum grit, etc. This cabinet is exclusively dedicated to abrasive media for surface blasting. By providing a protective enclosure, cabinets mitigate the need for extensive shot blasting safety equipment as they shield operators from microscopic abrasive particles.

Type of Shot Blasting Cabinet

- Suction Shot Blasting Cabinet

- Pressure Shot Blasting Cabinet

- Wet Shot Blasting Cabinet

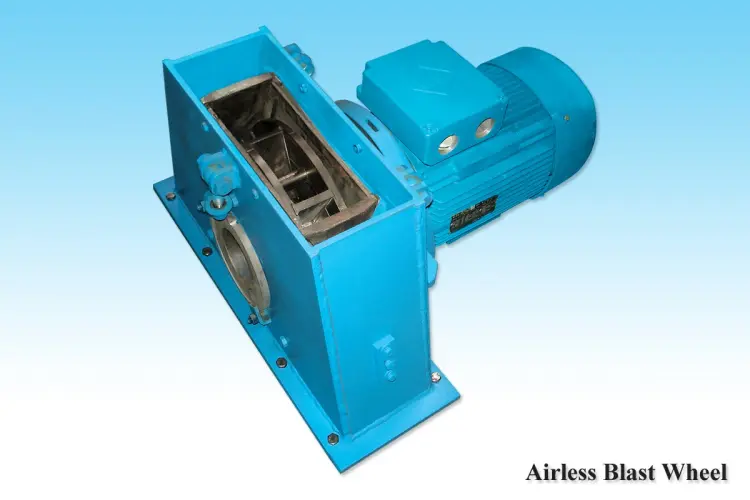

Airless Shot Blasting Machine

An airless shot blasting machine is also known as a wheel shot blasting machine manufacturers in Noida, India. The most popular blast cleaning approach is centrifugal wheel shot blasting, which is also the most cost-effective and environmentally beneficial program. A wheel shot blasting machine employs a concept that directly converts electric motor energy into kinetic abrasive shot energy by turning a turbine wheel. The turbine uses centrifugal force to deliver abrasive media steel shots in a regulated direction, speed, and quantity. The turbine functions similarly to a fan or centrifugal pump.

Type of Airless Shot Blasting Machine

- Table Shot Blasting Machine

- Tumblast Shot Blasting Machine

Table shot blasting machine

The table shot blasting machine, also referred to as the Swing Table Shot Blasting Machine, is equipped with rotating tables for loading components. These machines employ automatic shot blasting to descale and eliminate rust from components as they spin on the rotating Turn Table. A table shot blasting machine is a specialized equipment used for surface treatment tasks, particularly in industries such as automotive, aerospace, and manufacturing. It features rotating tables that facilitate the loading and cleaning of components. As the table rotates, the blast wheel positioned on top effectively removes rust, scale, and other surface contaminants. This process ensures thorough and uniform cleaning of the workpiece. Table shot blasting machines are known for their efficiency, precision, and ability to handle various types of materials and component sizes.

| S.NO | Description / Model | AWST-750 | AWST-900 | AWST-1200 | AWST-1800 | AWST-2440 |

|---|---|---|---|---|---|---|

| 1. | Swing Table Die (mm) | 750 | 900 | 1200 | 1800 | 2440 |

| 2. | Work Load Capacity (Kg.) | 350 | 400 | 750 | 2500 | 4500 |

| 3. | Turbine Size (D x W} | 305 x 63 | 395 x 63 | 495 x 63 | 495 x 63 | 63 x2 |

| 4. | Turbine (HP) | 75 | 15 | 20 | 20 | 20x 2 |

| 5. | Dust Collector Capacity | 3 HP | 5 HP | 7.5 HP | 7.5 HP | 10 HP |

| 6. | Total Power Consumption | 16.5 HP | 25 HP | 30 HP | 30 HP | 56 HP |

Tumblast Shot Blasting Machine

This equipment is perfectly suited for the automated and efficient shot blasting of castings and metallic components of varying sizes. These components are inserted into the Tumbling Barrel, making these Tumblast shot blasting machines suitable for a diverse range of components and manufacturing needs. They excel in mass-producing small tumbling components with sizable batch sizes. Manufactured with precision, these machines are designed for seamless integration with automated loading and unloading systems.

| S.NO | Description / Model | AW-TB-2027 | AW/-TB-2736 | AW-TB-3642 |

|---|---|---|---|---|

| 1. | Work Load Capacity Ka. (CFT) | 100(2) | 250 (5) | 500 (10) |

| 2. | Max. Weight of each component (Ko.) | 10 | 15 | 35 |

| 3. | Turbine Size (D x W} mm | 305 x 63 | 395 x 68 | 495 x 63 |

| 4. | Turbine (HP) | 7.5 HP | 15 HP | 20 HP |

| 5. | Dust Collector Capacity | 3 HP | 5 HP | 7.5 HP |

| 6. | Tota Power Consumption (HP) | 16.5 HP | 25 HP | 30 HP |

Shot Blasting Machine Price in Noida

The cost of Shot Blasting Machine Manufacturers in Noida varies depending on the specific type of shot blasting machine and the capacity of its abrasive tank. AWSFS Enterprises stands out as a leading provider in Noida, offering a range of shot blasting solutions including portable shot blasting machines, tumblast shot blasting machines, sand blasting machines, shot blasting rooms, grit blasting machines, and abrasive blasting media. They provide these products at competitive prices without compromising on quality.

Furthermore, AWSFS Enterprises offers specialized services tailored to the diverse industrial requirements of India. These include options such as shot blast glass beads and premium shot blast nozzles, providing extensive choices to meet various industrial needs.