AeroWheel Shot Blasting is a technique that no metal industry owner can function without. It is used in almost every metal-using industry, including aerospace, construction, automotive, foundry, rail, shipbuilding, and many others. It is used to clean, induce strength (via shot peening), or polish metal surfaces.

Shot Blasting machines have become an indispensable part of the metal building and steel structure industries. This blasting technique offers significant advantages for the protection and maintenance of steel and metal products.

Before we look at how a shot blasting machine works, let us look at some of the benefits that make this technique so important in the metal industry, which are listed below:

The Benefits of AeroWheel Shot Blasting

- Corrosion Removal: This is the most preferred technique for removing all types of rust and corrosive materials from metal and steel surfaces without reducing the product’s strength or leaving its base unaffected.

Corrosive deposits that commonly form on surfaces include:

- Rust

- Chemical Stains

- Mill Scale

- Faded or Chipped Paint

- Heat Treatment Scale

- Surface Preparation: This method of shot blasting suppliers is way far from the most effective and efficient method of preparing a metal surface before painting or coating. It has a high blast pattern accuracy and a very strong bond between the blasted surface and the protective coating. The technique aids in the detection of all types of flaws and errors. It also extends the life and durability of any future coating.

How Does an AeroWheel Shot Blasting Machine Work?

Environmental Considerations: This shot blasting machine technique is one of the few that provides environmentally friendly options for corrosion removal and surface preparation:

- Abrasion is the only method used to clean the surface of metal products.

- There are no chemicals utilized during the entire process.

- Acids are not employed at any stage of the procedure.

- The only cleaning necessary is for the actual pellets.

- A strong vacuum and dust collection system removes all blasted steel or media dust.

In addition, the process allows for the freedom and convenience of recycling the materials used in the process.

Shot Blasting Machine AeroWheel Technologies

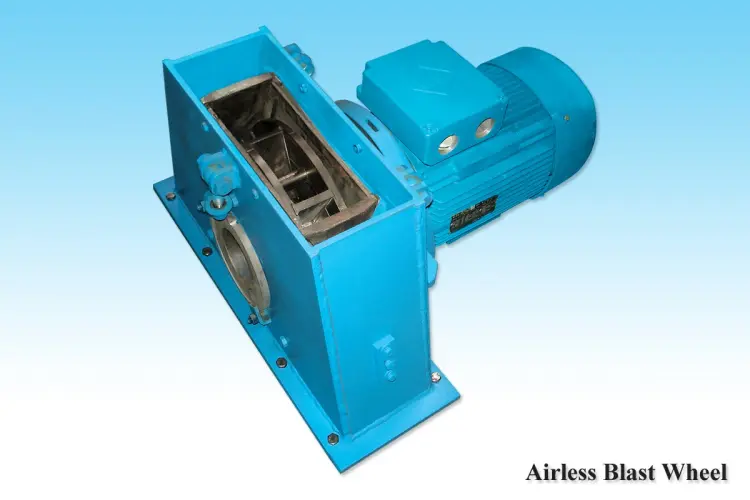

Shot blasting machine manufacturers use abrasive materials to clean, reinforce, and polish surfaces. These shot-blasting machines use a variety of technologies, including pneumatic power and airless shot blasting, to provide efficient and general surface treatment.

Two technologies are used in the blasting process:

- Wheel sandblasting (Air Less Shot Blasting)

- Air Blasting Technique (Pneumatic Shot Blasting / Air Operated Shot Blasting)

AeroWheel Shot Blasting Equipment

Let us now examine how the shot blasting machine works after we have gained a thorough understanding of the process:

To remove a layer of the surface and impurities from the surface of metal and steel products, shot blasting machines use a mechanical method of propelling abrasive using a centrifugal wheel.

There are three primary reasons why a product must be blasted before it is finished:

- It descales and cleans the surfaces.

- Improves paint adhesion by roughening the surface of metal products.

- Reduces maintenance costs by extending the life of the coating.

- This machine is used to clean the surface of finished goods of unwanted corrosion and metallic waste.

This is done to make the surface more uniform and smoother for a better finish after painting or applying other applications.

The process can also be used to remove rust, roughen the surface, and for further fabrication.

The shot blasting machine is used to clean the rough edges of various automobile parts or any other molding parts with sharp and uneven surfaces.

This shot-blasting machine manufacturer’s process is extremely important, but how exactly does a shot-blasting machine work?

The Machine’s Operation

A controlled stream of abrasive shot material is propelled towards the metallic or steel surface that needs to be shot blasted as part of this blasting technique. A blast wheel can be found at the heart of the machine. As soon as the wheel begins to rotate, the metallic abrasives or shot media are channelled towards its centre. The abrasives are accelerated and hurled in the direction of the surface being prepared for finishing from this position onward.

Following the completion of this process, the contaminants and media rebound into a separation system that contains the dust collection system. The dust collector, as the name implies, is in charge of collecting or removing pulverised media, contaminants, or dust.The remaining media is recycled by returning it to the storage hopper, where the particles can be saved for future use.

Table shot blasting machine

The table shot blasting machine, also known as the Swing Table Shot Blasting Machine, features turning tables for component loading. This shot blasting table flies on the door swings the interior surface of the cabin, while the blast wheel on top cleans the component.

The Machines use automatic shot blasting to descale and remove rust from jobs spinning on the spinning Turn Table.

After blasting, shots fall into the cabinet’s hopper and are gravity-fed to the bottom screw conveyor. Dust particles created in the system are captured in a series of filters.

| S.NO | Description / Model | AWST-750 | AWST-900 | AWST-1200 | AWST-1800 | AWST-2440 |

|---|---|---|---|---|---|---|

| 1. | Swing Table Die (mm) | 750 | 900 | 1200 | 1800 | 2440 |

| 2. | Work Load Capacity (Kg.) | 350 | 400 | 750 | 2500 | 4500 |

| 3. | Turbine Size (D x W} | 305 x 63 | 395 x 63 | 495 x 63 | 495 x 63 | 63 x2 |

| 4. | Turbine (HP) | 75 | 15 | 20 | 20 | 20x 2 |

| 5. | Dust Collector Capacity | 3 HP | 5 HP | 7.5 HP | 7.5 HP | 10 HP |

| 6. | Total Power Consumption | 16.5 HP | 25 HP | 30 HP | 30 HP | 56 HP |

Tumblast Shot Blasting Machine

The equipment is ideal for automatic and effective shot-blasting suppliers of castings and metallic components of various sizes. The components are loaded into the Tumbling Barre! These Tumblast shot blasting machine manufacturers are ideal for a wide variety of components and manufacturing requirements. This shot blasting machine works well for mass-producing small tumbling components with large batch sizes. The machine is manufactured with precision to allow for easy integration with automated loading/unloading systems.

| S.NO | Description / Model | AW-TB-2027 | AW/-TB-2736 | AW-TB-3642 |

|---|---|---|---|---|

| 1. | Work Load Capacity Ka. (CFT) | 100(2) | 250 (5) | 500 (10) |

| 2. | Max. Weight of each component (Ko.) | 10 | 15 | 35 |

| 3. | Turbine Size (D x W} mm | 305 x 63 | 395 x 68 | 495 x 63 |

| 4. | Turbine (HP) | 7.5 HP | 15 HP | 20 HP |

| 5. | Dust Collector Capacity | 3 HP | 5 HP | 7.5 HP |

| 6. | Tota Power Consumption (HP) | 16.5 HP | 25 HP | 30 HP |

Safety is the main concern when it comes to shot blasting machines

When using shot blasting machines to treat diverse materials, safety remains a top priority. As a result, shot-blasting machine manufacturers prioritize including improved safety elements into their designs, protecting users from potential threats. These firms follow strict safety requirements, adopting durable enclosure systems and automated controls to reduce operational risks. Shot blasting machine manufacturers prioritize safety, offering dependable solutions for a wide range of industrial applications that protect both personnel and equipment. Some of the concerns are:

- Metal dust can cause major health issues because metals like calcium, and manganese are very harmful when breathed.

- Dust also gives major concerns like having issues with respiratory disorders, which may ultimately cause major harm to the body of a person.

Shot blasting machine manufacturers provide many benefits for enterprises, but the workers or specialists in charge of carrying out this procedure must take security considerations seriously. This occurs because these specialists are continuously exposed to a wide range of hazardous scenarios while blasting various surfaces.

As a result, it is best to pass on the shot blasting process to qualified specialists who understand the necessary safety precautions and use protective gear, masks, and shoes. It is strictly pushed to use the media blasting technique under medical supervision. All workers must protect not only their eyes and bodies but also their ears.